New Cut-and-Cover Construction of the Hagnau Tunnel

As part of the Schänzli maintenance project, the Hagnau Tunnel was demolished and reconstructed as an open building pit. It is located along the SBB railroad embankment with seven tracks running above the tunnel. It was required to maintain the operation of the railroad and the national motorway during the entire construction period. This project provides an insight into innovative planning for construction in and/or on existing structures. This technical article was awarded first place as one of two presentations at the Colloquium as part of the Swiss Tunnel Congress 2023.

1 Schänzli Maintenance Project

1.1 Overall Project Overview

The FEDRO Schänzli maintenance project in the canton of Basel-Landschaft involves comprehensive repair of the motorway section from the Hagnau junction to the Muttenz south junction on the A2 and A18 motorways as part of several sub-projects. The route was previously repaired over a length of around 10 km. In addition to the construction and extension of noise barriers, the road surface was essentially replaced with low-noise surface material. In addition, the motorway entrances and exits were renovated throughout the project perimeter. Various engineering structures were repaired, strengthened, or partially rebuilt. Where possible, lane configurations were rearranged to optimise traffic flow and increase road safety. Various environmental protection measures were implemented as part of the project. Drainage and seepage pipes were repaired, a new road wastewater treatment plant was built in the Muttenz south junction area and an emergency basin was constructed for the Schänzli Tunnel.

The project was named after the Schänzli Tunnel, both tubes of which were comprehensively repaired. In addition to large-scale concrete repairs, the pavement and the adjacent shoulders were also renewed here. Drainage and fire-fighting water lines were replaced. An additional escape route was built to increase tunnel safety.

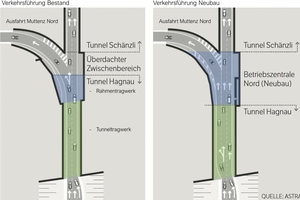

The Hagnau Tunnel is located ahead of the Schänzli Tunnel. When the maintenance concept was drawn up, it had already been decided to demolish the tunnel and build a new one. The junction area between the two tunnels includes the Muttenz north exit. In this area, a new tunnel operations centre was built to house the necessary technical infrastructure for the Schänzli and Hagnau tunnels. The tunnel is accessed above ground from Birsfelderstraße.

The entire project was carried out between 2017 and 2022. The costs have amounted to around 240 million Swiss francs.

1.2 Overall Project Goals

The following objectives were pursued with the overall renovation of the motorway section from the Hagnau junction to the Muttenz south junction. An operating time of at least 15 to 20 years had to be ensured, with as little intervention as possible. The elimination of accident hotspots and thus the improvement of traffic safety was one of the main objectives and was achieved by optimising lane arrangements and, where possible, lane add-ons. In doing so, the current standards and guidelines needed to be complied with as far as possible. When implementing maintenance projects and construction in the vicinity of existing structures, there are many restrictive boundary conditions that also had to be taken into account and harmonised according to various specifications.

2 Hagnau Tunnel Sub-Project

2.1 Situation and Overview

The centrepiece of the maintenance project is the Hagnau Tunnel. It is located between the motorway access road in the north and the Muttenz north exit and Schänzli Tunnel junction area in the south. The sub-project section

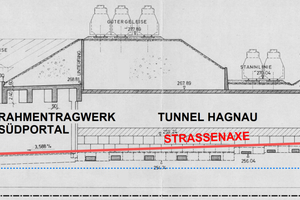

is around 100 m long, with 60 m making up the Hagnau Tunnel and 40 m making up the junction area. The Hagnau Tunnel is located entirely within the SBB railway embankment. Seven tracks run across the tunnel, including the main Olten–Basel railway axis tracks.

The implementation timeframe for the Hagnau Tunnel sub-project was between 2017 and 2020. The costs for demolishing and rebuilding the tunnel and the new operations centre amounted to around 60 million Swiss francs.

2.2 Existing Tunnel and Geology of the Railway Embankment

Since the middle of the 19th century, there has been a railway line running along a filled embankment in the Hagnau region, which has always been crossed by a road. With the construction of the Muttenz marshalling yard in the 1920s, the railway embankment needed to be extended. In this context, the Hagnau Tunnel was constructed using open-cut construction with a width of 8 m and a length of about 60 m.

In the 1970s, the Hagnau Tunnel became part of the then new national motorway. The route had to be adapted to the new alignment and lowered by an estimated 4 m, so that the existing road was supported. With the existing width of 8 m, traffic in the tunnel could run in two lanes; there was no space for a hard shoulder. At the same time as the Hagnau Tunnel was supported, the new Schänzli Tunnel, with a width of 10 m, was built to the south.

By lowering the level of the road, massive support structures were required in the junction area. In the area of the existing railway embankment, a prestressed frame structure was realised as an extension of the Hagnau Tunnel. The support structures were built in an open construction pit, for which the railway embankment was secured with a back-anchored element wall. The area between the frame structure and the Schänzli Tunnel was covered with a sheet of metal for noise reduction and lighting purposes.

In order to create space for further railway traffic, embankment backfills were added. Due to section based and time delayed construction, the railway embankment consists geologically of different backfill materials. Old excavation pit closures and residues from construction support measures also form part of the embankment. Birch gravel is located underneath the artificial embankment backfill, which has a groundwater carrier with an average thickness of about 5 m and seasonal fluctuations of 1 m. The tunnel floor is not in the groundwater’s direct sphere of influence. Tertiary cyrene marl lies beneath the birch gravel. This layer has a quasi-horizontal surface under the tunnel structure.

2.3 Boundary Conditions

The circumstances described above gave rise to various constraints that had to be taken into account when constructing the existing structure. The top priority was the safe and smooth operation of the national motorway and the adjacent modes of transport.

As described in the introduction, experts decided that the existing Hagnau Tunnel should be demolished and rebuilt as part of the maintenance concept. The decisive factors for this project were, on the one hand, the service life achieved and the condition of the tunnel, as well as the existing dimensions. Due to the extension built in the 1970s, the height-to-width ratio was constricting and the lighting conditions in the tunnel were poor, both of which had negative effects on excavation comfort and safety. In addition, the lane arrangement was not optimal. Since the Muttenz north exit is a left-turn exit and was designed without a deceleration lane, there was an accident hotspot in the junction area with the Schänzli Tunnel, which had to be eliminated. Relocating the exit to the right-hand side of the motorway was not an option due to the site conditions.

Geometric constraints constitute further boundary conditions when building in the vicinity of existing structures. In the case of the Hagnau Tunnel, these include the engineering structures of the Hagnau junction to the north. The motorway access from Gellertstraße leads over a bridge whose supports are founded directly in front of the tunnel portal. The arrangement of the supports determines the maximum possible width of the carriageway; a lane addition was not possible here. To the south of the Hagnau Tunnel, the Muttenz north exit and the Schänzli Tunnel junction area border the construction project.

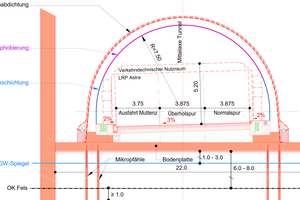

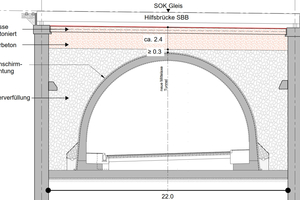

Building in the existing railway embankment, which was in operation, provided further constraints. The height of the tunnel is limited due to the existing tracks, which had to be taken into account for the feasibility and design of the new tunnel. Rail traffic had to be maintained during the entire construction period. Train detours on the SBB’s main railway axis between Olten and Basel were inconceivable in this bottleneck area. Therefore, all tracks had to be guided over the building pit via temporary auxiliary structures. In order to keep the costs within limits, standard auxiliary bridges from the SBB were used where possible, which, in turn, determined the width of the excavation pit with their own widths and thus also influenced the possible tunnel width. Six bridges were rented from the SBB. In order to install them, a switch had to be moved in the area of the building pit and the track geometry had to be adapted.

Another switch in the highest railway line area could not be moved. This was a crucial point of the project, as the track geometry was not adaptable. As a solution, a 25 m long temporary steel bridge was built especially for the project. As a Swiss-wide novelty, the switch’s sleepers were placed and fixed directly on the cross girders.

2.4 Widening the Hagnau Tunnel

Under the aspect of increased traffic safety and to eliminate the accident hotspot in the junction area, the tunnel profile was planned to be widened from two to three lanes. The lane addition gives left-turners into the Muttenz north exit a separate lane. The normal lane and the passing lane lead straight ahead into the existing Schänzli Tunnel. Figure 3 shows the situation before and after constructing the new tunnel.

The new Hagnau Tunnel was built in the same location as the existing tunnel and with the same length of around 60 m, using the cut-and-cover method. For the cut-and-cover tunnel project, the currently valid principles for the construction of a new tunnel according to the FEDRO technical manual had to be adhered to. A tunnel vault with a radius of 7.5 m and a horizontal floor slab 70 cm thick was planned. The vault has a concrete cross section of 60 cm, which was widened to 80 cm in the base area.

To seal the tunnel, a classic umbrella seal consisting of fully bonded PBD membranes and 10 cm of protective mortar was applied. Drainage pipes were installed on both sides of the tunnel, and a drainage niche was created on both sides of the tunnel for maintenance.

On the inside, the tunnel was waterproofed as a standard in accordance with the FEDRO technical manual and top-coated up to a height of 4 m.

The route has a constant longitudinal and transverse slope of 3%, allowing wastewater to drain off. Drainage takes place longitudinally in the direction of the Schänzli Tunnel and, from there, into a common storage basin. An additional fire-fighting water pipe was also laid jointly in the Schänzli Tunnel and the Hagnau Tunnel.

The shoulders are equipped with cable conduit blocks with eight 120 mm cable conduits each as a standard, plus a 150 mm cable conduit on one side. The two sides are connected with two cross-passages. The new Hagnau Tunnel is lit with individual lights along the roof ridges. Due to the widened cross-section, the lighting conditions in the tunnel were massively improved, which also has a positive effect on road user safety. The portal wall in the north was rebuilt as a retaining wall element and connected to the existing structure. In the junction area on the south side, the new cut-and-cover tunnel connects directly to the new operations centre.

2.5 Challenges

In addition to the boundary conditions described above, the following challenges were relevant for the further course of the project and the subsequent implementation of the construction measures.

Due to the inner-city location, the issues of working hours, noise and vibration emissions had to be handled sensitively. Despite the preferred daytime working hours, some work in the track area as well as on the national motorway had to be carried out at night and on weekends. For the narrow time windows, absolute adherence to deadlines was required. Otherwise, the impact would have been immense, especially on the railway traffic in connection with the main Olten–Basel railway axis.

In principle, construction was required to be carried out while the national motorway and the railway were in operation. With a traffic volume of around 62 000 vehicles per day, a reduction in the number of lanes was not possible. To guarantee capacity, a separate diversion lane was created outside the construction site perimeter. This meant that the national motorway could be reduced to one lane in the construction site area, and access to the adjacent Schänzli Tunnel was guaranteed. The Muttenz north exit also had to be kept open to the greatest possible extent, except during a few construction phases.

Work was carried out under very cramped conditions in the construction pit next to the existing and newly constructed cut-and-cover tunnel. The excavation support with braces ran directly above the roof ridge of the tunnel. The space conditions had an impact on the choice of equipment and the construction procedures. A high-voltage overhead line runs across the railway embankment, which had to be taken into account when constructing the excavation closure from the railway embankment.

The location of the cut-and-cover tunnel along the railway embankment posed further challenges. Due to the track system’s high sensitivity, low-settlement and low-deformation construction support measures were unavoidable. A certain robustness to the structures and safety with regard to their behaviour in the railway embankment was required. Since the building pit closure was also the support for the SBB’s auxiliary bridges, high demands were placed on the accuracy of construction.

2.6 Concept & Strategy

Based on the challenges described above, requirements were formulated and concepts and strategies for the optimal handling of the project were developed. Project requirements regarding minimum road and rail closures, while guaranteeing the safety of all participants and users, were decisive for the chosen concepts.

The following strategies, among others, were pursued to handle the project in the best possible way:

An agreement was made with the SBB to allow a few weekend closures per railway line for building the construction pit (large bored piles) and the installation and removal of the auxiliary bridges. The closures were estimated at 48 to 56 hours. The aim was to optimise the disruption to rail traffic to a minimum and to dispense with a large number of standard night closures (approx. 6 to 8 hours) for alternative construction methods (retaining walls).

Optimising the rigidity and robustness of the construction pit through the use of large bored piles with the aim of counteracting movements and settlements in the railway embankment and thus minimising maintenance work on the part of SBB. In the preliminary project, the standard 6 to 8 hour night closures of the tracks meant that the retaining walls had to be built.

The detailed planning of weekend closures, construction logistics and construction support measures was carried out in an early project phase. This meant that track closures could be reserved in good time and a safe and efficient process could be guaranteed.

Bonus/malus incentives were defined for the contractor with regard to restrictions on the national motorway, so that the construction time could also be further optimised during implementation.

Detailed 3D models were created during project planning. Within the framework of the BIM method, collision and coordination checks were carried out on the basis of the model. This made it possible, for example, to check overlapping bolt positions of various excavation supports and to optimise the arrangement of the bolts, thereby avoiding conflicts.

3 Construction Project

3.1 Installation Site, Site Access and Logistics

Along the Birsfelderstraße to the south of the railway embankment, an installation and logistical transfer point for truck transports was created. A ramp, approx. 7 m high in its

final state, secured with an anchored back-up wall and element wall, ensured access to the railway embankment. In the area above the existing south portal of the tunnel, the existing element wall from the 1970s was reactivated and the bolts securing the construction pit were newly constructed.

Access to the construction site was impossible at the north portal at the level of the national motorway. To create the construction pit, the motorway access ramp was briefly used as a logistical transfer point. Logistics options via rail were only used for transporting the drilling and excavation equipment for work in the track area and for the SBB auxiliary bridges.

3.2 Construction Pit Closure – Solutions in Special Civil Engineering

An open construction pit was planned to expose the existing Hagnau Tunnel and its new structure. Since the bottom of the excavation pit is above the groundwater level, a tight pit closure was not required. Due to various criteria, such as the required robustness of the construction pit, the minimum settlement requirements and the minimum intervention with the railway traffic, a detached bored pile wall was planned. This was constructed with large bored piles of 1.3 m in diameter. The piles, which were around 22 to 30 m long, were embedded in the adjacent rock below the bottom of the construction pit. The large bored piles were installed during long weekend closures from the track area, whereby a maximum of two tracks could be taken out of service at the same time.

To brace the piles, and as supports for the SBB auxiliary bridges, the piles were connected with solid 80 cm high head beams. Between the head beams and thus directly underneath the auxiliary bridges, the first layer of braces was set, executed with 60 cm high double H-beams.

The construction pit was then excavated in small stages and the excavated material was transported away via the Birsfelderstraße installation site. The existing tunnel almost filled the entire pit. Several reinforcement levels were planned. Thanks to an innovative construction option with multibond anchors (multi-stage anchors), proposed by the contractor, it was possible to dispense with two reinforcement layers and thus optimise the space conditions in the construction pit.

As described in the challenges presented, at least one lane had to remain in operation in the construction site area. The location varied depending on the construction phase and was first routed centrally through the existing tunnel. To protect the national motorway from chipping during excavation, a protective wooden cover was constructed while maintaining the clearance profile in the existing tunnel. The tunnel walls were supported against each other with struts for safety reasons.

3.3 Hagnau Tunnel Demolition

The tunnel was planned to be demolished by cutting in very small stages. It was possible to optimise this process in close cooperation with the contractor. The vault part of the tunnel and the prestressed frame structure in the junction area were demolished in two continuous weekend and additional overnight closures of the national motorway, using the largest demolition excavator in Europe (A-Rex). Figure 8 shows the intermediate state after demolishing the frame structure and the tunnel ridge between the two demolition weekends. The carriageway was then moved to the former right-hand lane in the tunnel. The construction site section was secured with vehicle restraint systems and construction walls installed on top. Then, the eastern tunnel wall was demolished beneath traffic. The same procedure was applied for demolishing the western tunnel wall. Traffic flow was maintained for the preliminary work and in sections for constructing the base slab.

3.4 Constructing the New Hagnau Tunnel

To transfer forces and to avoid settlement of the tunnel and the railway system above it, micropiles with a rock embedment of at least 1 m were constructed in the area below the base of the arch. The base slab of the tunnel was constructed in sections. With the force-locking connections across the entire width of excavation, it also assumed the function of the final bracing level.

The new cut-and-cover tunnel was shuttered conventionally and constructed in six sections of 10 m each. Furthermore, traffic had to be maintained. The traffic lane was routed through the centre of the formwork carriage and protected with a wooden structure. After stripping and dismantling the formwork carriage, the lane in the tunnel was moved back one side at a time. This made it possible to construct the shoulder in the tunnel and install the operating and safety equipment.

On the south side, the tunnel connects directly to the new operations centre. To the north, the portal wall was rebuilt as a supporting wall for the railway embankment. To restore the railway embankment, the construction pit was symmetrically backfilled in stages below the last layer of struts. Due to time-related reasons, it was not possible to guarantee closure weekends that were long enough to allow the removal of auxiliary bridges, struts and the systematic backfilling and compaction to be carried out professionally. For logistical reasons, it was not possible to remove the struts directly under the auxiliary bridges in advance. Therefore, the area from 1.8 m below the last layer of struts to the top edge of the head beam was backfilled with seepage concrete.

4 Lessons Learned

The complexity of the project required constructive and cooperative collaboration during realisation as well as innovative implementation by the contractor. Improvements were often found and implemented through joint solution building and communication. However, it was also important to use robust and proven solutions to minimise the risks during construction in the SBB railway embankment.

Innovations go beyond technical solutions. Thus, the first aspects of BIM (building information modeling) planning were applied. Basically, 3D models were created, from which conventional 2D plans were then derived. The 3D models helped identify and directly solve conflicts in planning. For example, using the model, the position and angle of bolts for the various construction pit closures in the south portal area were optimised, and overlaps were ruled out. Stake-out points were generated directly from the models and made available to the contractor in digital form. The carcass models served as the basis for the reinforcement models, which were also created in 3D. In the area of BIM2Field, cases of application were implemented with regard to construction site management, quality

assurance and defect management. The BIM360 CDE platform from Autodesk was used for this purpose.

My personal contribution to the project comprised a lot of planning – from the initial and detailed project phases through to supervision of the DAW (documents and work implemented). Specifically, I was responsible for planning the large bore piles with an associated logistics concept and excavation as well as the associated construction phase planning, including track closures. Further topics included the development of the BIM strategy and the application cases, the monitoring concept and various small structural analyses and pre-dimensioning the construction pit. I also hat the opportunity to design and dimension the core piece of the sub-project the cut-and-cover tunnel in Hagnau, and accompany its construction as construction supervisor during implementation. I am also particularly proud of the development, project planning and dimensioning of the special auxiliary bridge with a mounted switch, without which the project could not have been implemented.

5 Looking Back

The cut-and-cover tunnel, the operations centre and the restoration of the track system were completed and ready for operation at the end of 2020.The construction proceeded without any major incidents while the national motorway and railway were in operation. Construction time could be considerably reduced during implementation. The open construction site provided the public with numerous exciting insights into the activities of infrastructure construction.