Brenner Base Tunnel: Mixing Pump Caters for Firm Ground beneath Invert Segments

The Brenner Base Tunnel is a mega project within the TEN-T (Trans European Network-Transport) undertaken to expand and improve Europe’s infrastructure. The altogether 64 km long Brenner Base Tunnel will become the world’s longest rail tunnel in 2027 when the two main tubes open. Specialised journalist Roland Herr spoke on the construction site with Sebastian Grüllich (TBM construction manager of the STRABAG/Salini-Impregilo Consortium, contract section Tulfes–Pfons) and Hannes Papousek (managing director of MAI International) about the installation of the invert concrete segments for which the MAI 440GE mortar mixing pump was deployed.

Work is forging ahead intensively in all contract sections – both on the Italian as well as the Austrian side, and in the Tulfes–Pfons construction lot near Innsbruck (Austria) the 15 km long Ahrental–Pfons exploratory tunnel

had been driven all of 14.8 km in June 2019. Sebastian Grüllich, TBM construction manager in Tulfes–Pfons, describes the progress of the work: “Our contract section with STRABAG as technical manager embraces the production of around 40 km of tunnel, with some 25 km being tackled by drill+blast and approximately 15 km with an open Gripper Tunnel Boring Machine. The excavated cubic volume amounts to around 2.3 million m3. Furthermore, 430 000 m3 of structural concrete is being processed for the inner lining. A Gripper TBM from Herrenknecht with a boring diameter of roughly 8 m is applied to produce the exploratory tunnel, which is driven from the Ahrental access tunnel towards the south”.

Backfill Concept with MAI 440GE Mortar Mixing Pump

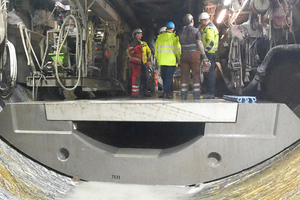

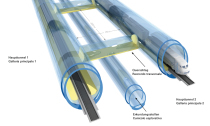

In the exploratory tunnel, invert segments are installed some 30 m behind the TBM cutterhead according to progress. They are backfilled with a dry mortar pre-mixed at the factory. Once the backfill concept had been given the go-ahead by the consortium STRABAG/Salini-Impregilo, the mixing pump MAI 440GE from the Austrian manufacturer MAI International GmbH, one of the worlds leading producers of grouting pumps in tunnelling, was chosen.

Sebastian Grüllich said the reasons for choosing this pump related to process safety and the dual mixing system assuring constant quality and consistency of the backfill mortar. In addition, a complete documentation was agreed on with the client for the pump’s most important operating data. As a result, within the scope of quality assurance the water-cement value of the installed cement can be verified retroactively. This is accomplished by means of the MAI LOG data logging unit, which records the corresponding data every 10 seconds. According to the manufacturer, this new technology sets standards in the field of real time data registration and recording of the quantities of water for documenting the water/cement ratio as well as pressure, grouting volumes, water flow and time for placing mortar and grouting.

Simple Operation, Low Maintenance Requirement

The most varied parameters on the mixing pump, which is placed directly at the point where the invert concrete segments are installed, can be set with scarcely any effort. The mortar can be backfilled with precision even given the rugged conditions prevailing on a tunnelling site.

“Operation of the equipment is self-explanatory so that anyone can operate it following a short period of instruction. As a result, a single person is capable of placing and backfilling the invert segments. Furthermore, the need for maintenance is reduced to a minimum thanks to the robust design”, explains Hannes Papousek, MAI International’s managing director. The compact mixing pump and the data logging equipment were assembled directly below the dry mortar container in October 2015 and since then roughly 7000 t of mortar were grouted.

Exact Coordination for Backfilling

Sebastian Grüllich described why it is so essential that the control and mixing process must be absolutely in harmony when the invert segments are backfilled: “Roughly 8 m behind the segment installation or backfilling area, the two lateral drive units of the TBM support run on the backfilled invert segments. The weight introduced by each drive unit amounts to some 75 t. Consequently, complete and secure backfilling is imperative in order to safeguard the immediate resilience of the backfilled invert segments. By separating the mixer and pump and the automatic process cycle the selected consistency of the backfill mortar is guaranteed during the backfill phase without visual monitoring on the part of the operator”.

The backfill mortar provides the bond between the invert segment and the rock. The mortar must be easy to process, possessing good flowability in order to achieve this as soon as possible when it is placed between the invert segment and the tunnel surface. Thus, the mortar mixing pump that is deployed must guarantee a constant quality and consistency at any time. The invert segments are backfilled unpressurised with a roughly 10 m long hose via the two lateral joints between the segment and tunnel surface.