Anchor Bolts attach innovative Overhead Contact Lines to Segments

The Katzenberg is Germany’s third longest rail tunnel. Since December 2012 trains have sped through the almost 9.5 km long rail tunnel at speeds of up to some 250 km/h. For this purpose the high-speed overhead contact lines Re 330 were anchored to the segments with bolts for the first time in Germany.

This new and partially upgraded route between Karlsruhe and Basle is numbered among Europe’s most important rail arteries. It now possesses 4 tracks to increase capacity and top speeds on the RhineValley line thus optimising rail transportation in the region as a whole. One of the most important sections of this project is the 9,385 m long Katzenberg Tunnel between Efringen-Kirchen and Bad Bellingen (District of Lörrach). The route runs practically in a straight line. The 2 bores are set 26 m apart. They are connected by 19 cross-passages set at 500 m intervals.

The tunnel was driven by mining means over a length of 8,984 m. Towards this end 2 shield tunnel boring machines were used in hard rock for the first time in Germany. The north and south accesses were tackled via cut-and-cover. Given an excavated cross-section of 95 m² the actual useful cross-section was reduced to 62 m². The inner shell was installed during the excavation and comprises around 63,000 segments. The individual curved precast concrete parts are 50 cm thick. The internal diameter of the completed ring shell equals 9.60 m.

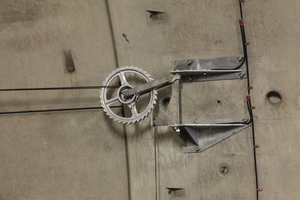

Engineers from Balfour Beatty Rail devised a modified high-speed overhead line Re 330 for speeds of up to 330 km/h with line feeder for single-track tunnels built with segments. For this purpose a process was developed in conjunction with fischer to fix the complete contact wire. In this connection the components of the overhead line system were not attached to anchor rails, which were already integrated in the prefabricated segments, but directly fixed to the segments with composite anchors and anchor bolts. Parallel to this the Katzenberg Tunnel was provided with its own earthing concept, whose components are also attached to the tunnel inner shell.

A standard support point gap of 48 m had to be adhered to when executing the attachments for the overhead line system. In addition the attachments could only be completed in an 8 cm thick drilling lane on the segmental ring, whose individual segments vary their position within the ring.

In order to comply with these high demands on accuracy for a Re 330 as well as to accomplish dust-free drilling, the Balfour Beatty Rail specialists developed 9 drilling templates for the various overhead wire components. Towards this end the surveyor drew the calculated drillholes on the special drilling templates, which consisted of aluminium and a surrounding rubber ring, upon which a vacuum suction device was set in order to ensure that any accumulating dust was removed directly during the drilling process. Extensive tests were carried out on site prior to the drilling operations.

FAZ II M16/50 A4 anchor bolts were use for fixing the posts for the beams with bracket and overhead wire at gaps of 48 m. The line feeders and the return conductors were fixed with FAZ II M16/50 A4 anchor bolts every 30 m. 11 high-bond anchors FHB II M20 A4 were installed to anchor the wheel tensioners set up at 1,150 m intervals (for tensioning the brackets and overhead wires).

FAZ II M10 A4 anchor bolts were applied to fix the component earthings in the base with drop-in anchors EA II M8 A4 used for earthing components in the roof as well as for the various electric sensors.

All told work on the roughly 9.5 km long Katzenberg Tunnel in the south of Freiburg progressed from June 2005 until December 2012.