Rail Technology for the Gotthard Base Tunnel

More frequent, faster, more direct and even more comfortable: the flat trajectory railway through the Alps will provide better connections on the north-south axis. Towards this end ultra-modern rail technology facilities are needed. These cater for rail services in the tunnel and link the new routes up with the existing network.

The first Swiss north-south high-speed route between Zurich and Milan including the Gotthard and Monte Ceneri tunnels is some 90 km long. Since 2009 work on installing the rail technology in the Gotthard Base Tunnel has been in progress: rails, points, contact wire, power supply, Telecom and a new signalling technique for up to 250 km per hour. The new rail link will enable more and faster trains to travel over it. These remain the desired targets since the people’s referendum in 1998 relating to financing the sophisticated rail modernisation scheme. This can first be facilitated through the rail technology following the actual building of the tunnel.

Rail Technology in the Gotthard Base Tunnel

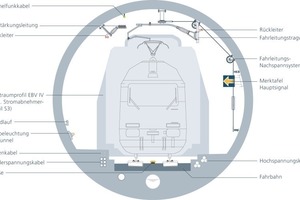

The rail technology embraces all components and systems, which belong to the rail technical system as such and which are thus of central importance for future operations (Fig. 1):

• the track

• electrical facilities for the power supply for the rail technology and tunnel-specific installations

• rail power facilities for providing energy for the trains travelling in the Gotthard Base Tunnel

• Telecom facilities for connecting with the outside

• Safety facilities for ensuring maximum security.

Track

The Gotthard Base Tunnel is being provided with a non-ballast track. Sleepers and rubber shoes are fixed in position. A major advantage of this type of track is that the individual elements can easily be replaced. As there is no rigid connection between the track grid and the track bearing plate it is even possible to replace sleepers at one side of the track only. In the Gotthard Base Tunnel the track bearing plate is located directly on the roughwork’s base invert.

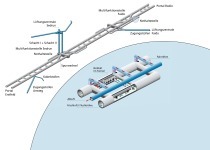

Rail Power Supply and Contact Wire Systems

The mixed traffic passing through the Gotthard Base Tunnel places high demands on the rail power supply and the contact wire systems. The rail technology specialists were forced to come up with technically sophisticated solutions. Thus for example passenger trains travelling at peak speeds of up to 250 km/h require a contact line that is as light as possible. However, the major power sources needed for the traction of heavy goods trains, for their part require large wire cross-sections. A conventional catenary line has emerged as the optimal solution for the Gotthard Base Tunnel. The system posses a large overall cross-section and the transit power supplies are largely guided through the feeder lines. As a result is it possible to construct a light version of the catenary lines, which is optimally geared to the mechanical requirements. In Switzerland all 16.7 Hz railway systems receive energy from a central high-voltage network, which is largely operated with 132 kV. Sub-stations are foreseen for the Gotthard Base Tunnel at the access tunnels in Amsteg and Faido, which provide the power supply. Further feeder stations for the Base Tunnel are located at the portals. At the north portal power is derived from the existing main line whilst at the south portal the new Pollegio sub-station is intended to fulfil the task (Fig. 2).

Infrastructural Power Supply

The 50 Hz power supply in the Gotthard Base Tunnel has to fulfil the highest demands regarding safety and availability. As a result the power supply is effected via 3 largely independent high-voltage networks to the north and south of the Alps. All consumers are provided redundantly and with the required independence.

Cable Systems

The tunnel contains only the most essential installations because extreme climatic conditions prevail there with temperatures of up to 40 °C and access for repair and maintenance is difficult. The cable network for the 50 Hz power supply embraces some 1,100 km of high-voltage and some 1,050 km of low-voltage cables. 1,100 km of fibre-optic cables was laid for data transmission purposes. The cables were laid in conduit blocks in the shoulders at the side.

Communication and Data Transmission

The rail technology is automated to a large extent. Consequently an extremely reliable system for transmitting information is required, both for transmitting data as well as speech. An important role is played here by the landline-based communication, which interlinks the various rail technology components within the Gotthard Base Tunnel to form a whole. These include the data network, which transmits the processing and operating data – and the communication system, which caters for line-bound speech requirements. Mobile communication media are used for operational purposes (GSM-R, radio systems, driver’s cab signalling) but the passengers too can take avail of the services of the public mobile network providers during their journey through the Gotthard Base Tunnel. An effective and highly available tunnel radio system is essential to assure the various services, which acts as a transmission and radiation medium.

Safety Systems

The safety systems serve to control and monitor the zones in which the trains are moving and offer an extremely high degree of automation. They connect signals, the track vacancy detection system and points with one another. It goes without saying that these central elements of the rail technology equipment have to comply with very high safety and availability standards. Even minor errors would lead directly to train delays or even dangerous situations. The Gotthard Base Tunnel’s safety systems comprise the following installations:

• Signal boxes and track vacancy detection systems, control of the point mechanisms

• Rail guidance technology including operation and display, train routing and other functions

• Driver’s cab signalling with route centre (Radio Block Centre) and transponders on the track.

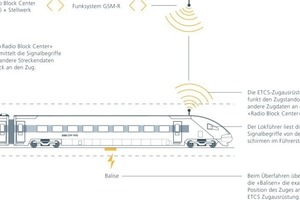

Driver’s Cab Signalling

The Gotthard Base Tunnel is to be equipped with the Europe-wide standardised signalling and train safety system ERTMS/ETCS (European Train Control System) Level 2. The signal box with conventional vacant-track detection facilities still serves as the basis for securing the track. The main difference to conventional train safety systems is to be found however in that electronic driver’s cab signalling is applied instead of fixed-point optical signals. The train driver obtains all relevant information via radio on the display in his cab. Driver’s cab signalling enables high speeds given shorter train frequencies. In the long term ETCS is intended to replace the many different train safety systems and train routing systems, which are applied within Europe but are incompatible. In this way a contribution will be afforded towards interoperability (Fig. 3).

Control Technology and Operation

The tunnel control technology represents the reliable, safe monitoring and control of technical systems in the overall Gotthard Base Tunnel system. The rail control system is responsible for the superordinated signal box display and operation, for detecting irregularities whilst accessing the Gotthard Base Tunnel and for connecting the safety systems to other systems. The entire operations on the Gotthard Axis from Arth-Goldau to the Italian border are controlled from the Centro d’Esercizio Pollegio (CEP) in Ticino. This embraces the control, monitoring and supervision of train traffic as well as the controlling of all technical, non operation-specific systems and installations for the Gotthard and Ceneri Base Tunnels. In addition the CEP also contains the central point for coordinating the maintenance team for the 2 base tunnels. This is also where emergency forces assemble should the need arise.

From the Works Contract to Installation – a long Way

The experience of the Swiss Federal Railways with various types of tendering for high-speed routes such as Zurich-Thalwil or Mattstetten-Rothrist and elsewhere in Europe with the Euro Tunnel, Cologne-Rhine/Main revealed that a general contractor’s tender incorporated the least risks. In this connection a detailed construction project is drafted as the basis for the general contractor’s tender. Subsequently a general contractor is commissioned to provide the planning, execute and implement the entire rail technology.

Risks

Inadequately defined restriction and distribution of risks remains a frequent bone of contention during the construction phase. Thanks to the chosen procedure it was possible to identify and clearly allocate the risks prior to the signing of the works contract. Even after the signing of the works contract the AlpTransit Gotthard AG continues to be responsible for particular risks:

• Exceeding the maximum temperatures defined in the works contract. Simulations indicated that the temperatures in the tunnel bores are extremely high compared with the existing Alpine tunnels.

• Changes to orders for political, legal and interface management purposes and in turn claim management. The changes to orders so far have mainly served to meet enhanced safety requirements, the modernisation of rail technology or improvements benefitting the population and environment.

The NEAT’S biggest Works Contract

The actual works contract for the rail technology governs the planning, development, manufacture, supply and assembly of the entire rail technology equipment for the Gotthard Base Tunnel including the open new north and south routes that were constructed, integration, commissioning and operation until acceptance of the project. Worth some 1.69 bill. CHF it represents the AlpTransit Gotthard AG’s biggest ever contract. On a worldwide scale it is also one of the largest contracts in the field of rail technology ever to be signed. The works contract for the rail technology was signed by the commissioned consortium and the AlpTransit Gotthard AG on April 28, 2008. This signified that work could thus commence.

Start of Work on the Rail Technology for the Gotthard Base Tunnel

Installing the rail technology in the Gotthard Base Tunnel represents a complex and sophisticated task. Good cooperation between the roughwork and equipping and the individual rail technology sectors is just as decisive as a flexible installation plan for ensuring that work is concluded in time within the desired cost frame. Installation of the rail technology and the entire commissioning phase will last roughly 8 years.

Following a year devoted to intensive planning and development initial work on installing the Gotthard Base Tunnel’s rail technology began in Ticino. Since May 2009 the responsible contractor has been engaged in building the access tracks from Biasca Station to the installation yard for the rail technology. From summer 2009 till spring 2010 living quarters for 230 workers, a canteen, assembly halls for preassembling the rail technology components, storage premises and storage areas in the open, a control centre for supervising construction site traffic in the tunnel and various works tracks were set up on the around 60,000 m² large installation yard area. The installation of the temporary and first permanent facilities in the tunnel from the south portal at Bodio started in May 2010. Work on the permanent slab track started in September 2010 (Fig. 4).

Installation of the Rail Technology

The complex marginal conditions involved with installing the rail technology represent a major challenge for the rail technology specialists. Correspondingly complex preparations were necessary prior to work commencing.

• It is either impossible or very difficult for tyred vehicles to cross, overtake or turn in the two 57 km long single-track bores of the Gotthard Base Tunnel. Furthermore only the 2 portals represent effective accesses to the tunnel system. As a result practically everything is transported by rail from the 2 main installation yards in Erstfeld (north portal) and Biasca (south portal).

• These in part extremely long transport routes necessitate intricate logistics. As work progresses distances of up to 40 km are involved.

• In addition extreme climatic conditions prevail in the tunnel. Many pieces of equipment are housed in cabinets and containers in order to protect them from the high temperatures and the air humidity. During the rail technology installation phase ventilation and air-conditioning improve the conditions for the workforce.

Track acts as Key for Installation

The rail technology is installed in each tunnel section in accordance with the same pattern. First of all temporary structures and cables are installed. Then the permanent slab track is put in position. It caters for the track-based transport logistics for the remaining activities. The catenary wire supporting structure is installed parallel to the equipping of the cross-passages. This is followed by wiring, connecting the data points and technical systems and finally commissioning (Fig. 5).

Sophisticated Material Logistics

In order to ensure that the proper rail technology components are available for installation at the scheduled time at the exact place in the tunnel, efficient material logistics is essential. Many elements are customised and have to be ordered in time, produced and delivered in the desired quality. The components are stored on the installation yards, preassembled and transported for assembly into the tunnel.

Commissioning

The Gotthard Base Tunnel is commissioned in a number of phases. After conclusion of the installation phase all components and systems are checked in partial tests to see if they are functioning. After the successful conclusion of these tests the commissioning as such follows. This is divided into 2 phases:

• Phase A:

The AlpTransit Gotthard AG as producer establishes the functionality and safety requirements of the Base Tunnel. By means of trial services lasting for months on end the interplay of the tunnel components is investigated extensively during a test phase.

• Phase B:

The test schedule is mainly the responsibility of the SBB AG, the Base Tunnel’s future operator. Only when it has been verified that operation with passenger and goods trains, deployment of staff and overcoming incidents function without friction, can the responsible Federal Office of Transport bestow the operating permit for commercial, scheduled services.

Faido-Bodio West Test Section

The western bore between Faido and Bodio is the first part of the tunnel to be fitted with the rail technology systems. As from 2013 trial services with speeds of up to 200 km/h will take place over this more than 15 km long section. In this way the complex interplay of all rail technology systems will be extensively tried out. The findings will be made use of for installing and commissioning the rail technology on the further sections of the 57 km long Gotthard Base Tunnel.

Building for the Future

More than 100 years ago the first rail network crossing the Alps was established in Europe. With the signing of the works contract and the start of work on the rail technology following the breakthroughs the tunnellers at the Gotthard Base Tunnel embarked on the final stage en route to a new age for traffic through the Alps.

When is High-Speed possible?

A rail route is described as a high-speed route when it allows speeds of at least 200 km/h. Travelling speeds on the AlpTransit Axis of between 200 and 250 km/h are permissible. A number of aspects should be observed here closely in this connection:

• Route alignment:

High speeds call for as straight a route alignment as possible with only slight gradients. Curves in the AlpTransit project must have a radius of at least 5,000 m. On the open route the gradient amounts to a maximum of 12.5 ‰ and only 8 ‰ on account of the increased air resistance in the tunnel.

• Safety:

Roads are not crossed for safety reasons – this calls for structures such as bridges or underpassages.

• Maintenance:

On account of the high frequencies and the high speed of the trains it is not possible to undertake maintenance work while a track is being used by trains. In order to ensure that work can progress safely on a track a safety margin of 5.5 m is adhered to. A protective barrier prevents the workforce from stepping on to tracks which are in use. In the event of maintenance work in the tunnel, the entire bore is closed down.

• Driver’s cab signalling:

Train drivers cannot identify stationary signals properly at high speed. As a result the signals must be communicated to the driver’s cab. The ERTM/ETCS system is to be applied for the Gotthard axis.